Where Precision Meets Scale

Located in Alkmaar, Mpumalanga,South Africa's premier macadamia region, the Golden Macadamias Processing

Facility stands as one of the largest and most advanced in the world. Designed to handle up to 30,000 tons

annually, it combines cutting-edge automation, climate-controlled storage, and predictive sorting to ensure

every nut meets the highest quality standards.

From rapid farm-to-factory intake to our validated pasteurisation system and ready-to-eat packing lines,

every step is built around food safety, consistency, and traceability. More than a facility, it's a

grower-owned investment in innovation and integrity, delivering world-class macadamias to global customers

who demand the best.

Innovation & precision drives everything

These subsidiaries together form the Golden Macadamias Group, ensuring seamless integration from orchard to end market. Golden Macadamias operates through two wholly owned subsidiaries:

Smart Curing Automation

Advanced systems monitor and manage curing — the critical first step in macadamia processing.

Climate-Controlled Cool Store

Our temperature- and humidity-regulated storage maintains nut quality for 8-12 weeks, allowing us to sort based on predictive lab data rather than relying solely on raw output.

Rapid Farm Intake

We move crop off the farm quickly to preserve shelf life and take full control of product quality from the start.

Ready-to-Eat Capability

Our dedicated RTE zone includes validated pasteurisation (5-log Salmonella reduction), giving us the flexibility to pack both bulk and ready-to-eat formats.

Partner Facilities

As the largest marketer of macadamias from the world’s top origin, we ensure unmatched supply security and consistency. We've expanded our footprint by partnering with leading processors in Kenya and Guatemala, bridging seasonal gaps and enhancing year-round availability.

Cold Storage & Export Efficiency

To support reliable export operations, NDX partners with trusted external cold storage facilities

located near key ports. These BRC-approved warehouses meet our strict internal standards and undergo

regular audits to ensure full compliance with global food safety regulations.

By streamlining logistics and maintaining premium storage conditions, we help our partners respond

faster to customer demand—without compromising on quality.

-

Strategic location for reduced transport times

-

Daily temperature monitoring for optimal product storage

-

On-site container loading once stacks are confirmed

-

Customer labels printed directly at the warehouse

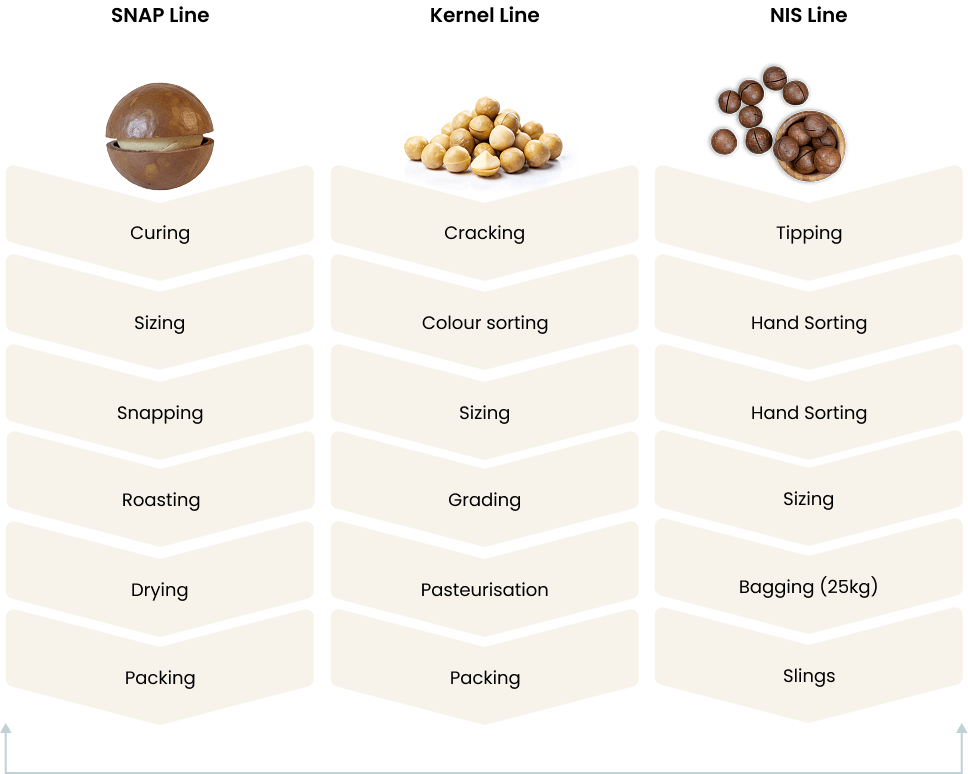

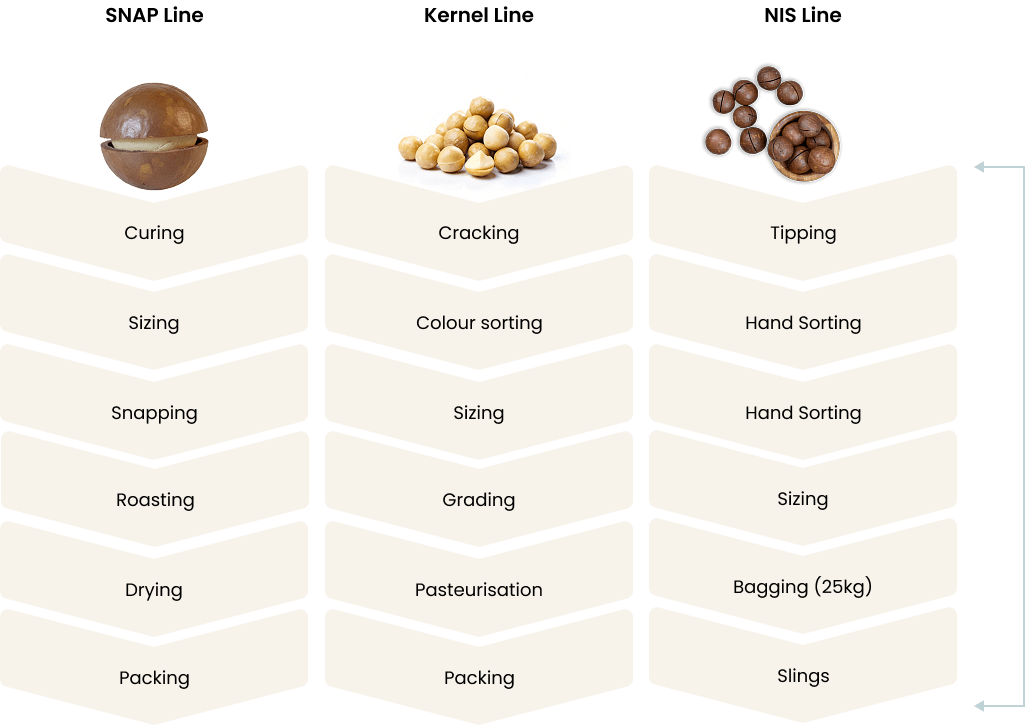

The Step-by-Step Journey

of a Macadamia Nut.

Every macadamia undergoes a carefully managed process to ensure the highest quality and food safety from farm to final pack:

It starts here

Golden Macadamia Facility

Processing Paths

Processing Paths

Depending on the product type, nuts follow one of three specialised lines:

Quality Control

From start to finish, our process is designed to maintain quality, traceability, and global food safety standards.

-

Pasteurisation

-

Metal Detection

-

X-ray Inspection

-

Final visual and manual checks

.jpg)

Export & Distribution

Export & Distribution